Custom Made Implant Manufacturing

Custom Made Implant Manufacturing

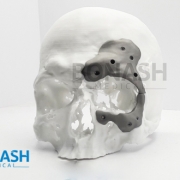

Introduction of direct digital manufacturing technologies that enable the fabrication of porous 3D printed implants with lattice and solid structures in one go from patient specific data has opened up a new horizon for the next generation of custom made implant.

In the very recent past ushering of metal additive manufacturing has introduced the direct fabrication of the titanium implants without the need for the template. This custom made implant will aim to confirm to the normalized shape of the part it replaces, with mechanical properties being close to that of the region of implantation.

In comparison to standard implants, 3d printed implants have many benefits:

- Superb shape matching

- Shorter surgery time and recovery time

- Can be used to reconstruct any skeleton structure

- Not palpable to the patient

- Possibility of obtaining very complex implant geometry

- High level of osseointegration by using scaffold structure inside the implant